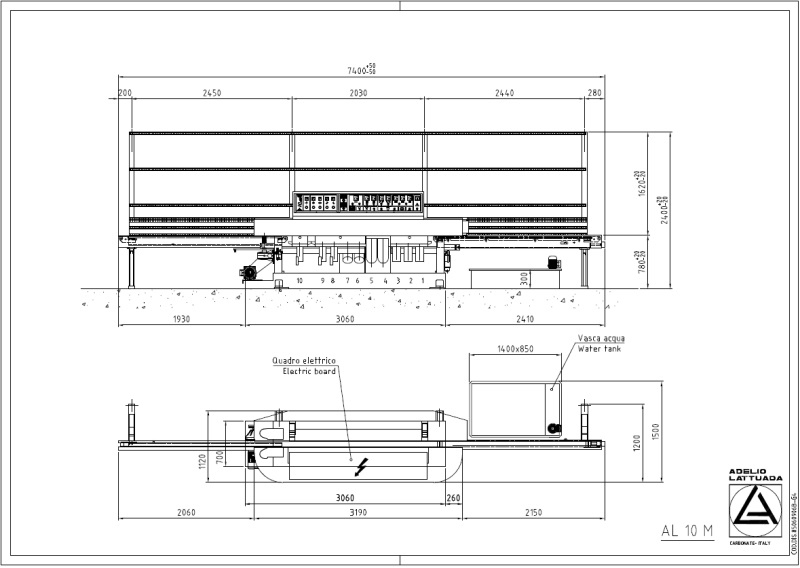

AL 10 M

Electronic straight-line edging machine for the processing of flat edge with arris, polished by cerium oxide.

Thanks to read outs placed on the control panel it is possible to set adjustments as working speed and glass thickness. Mechanic glass clamping system. In order to avoid the wheels wear and tear, a centralized lubrication system is fitted. The conveyor is composed by pads, made of a special material, which are mounted on precision chains. Automatic regulation of the arris wheels when the glass thickness change.

The wheels are fitted on spindles to which the movement is transmitted thanks to toothed belts linked to the engines. The polishing wheels intervention is automatic because it is controlled by a PLC. Adjustable inlet conveyor with which it is possible to adjust the glass removal up to 5 mm. Low voltage control panel (24V). All the electrical components are in accordance with CE and international standards.

- Downloads/Info

- Videos

- Technical Info

Videos

Technical Info

Wheel Configuration and Technical Info

AL5 – AL10M.pdf