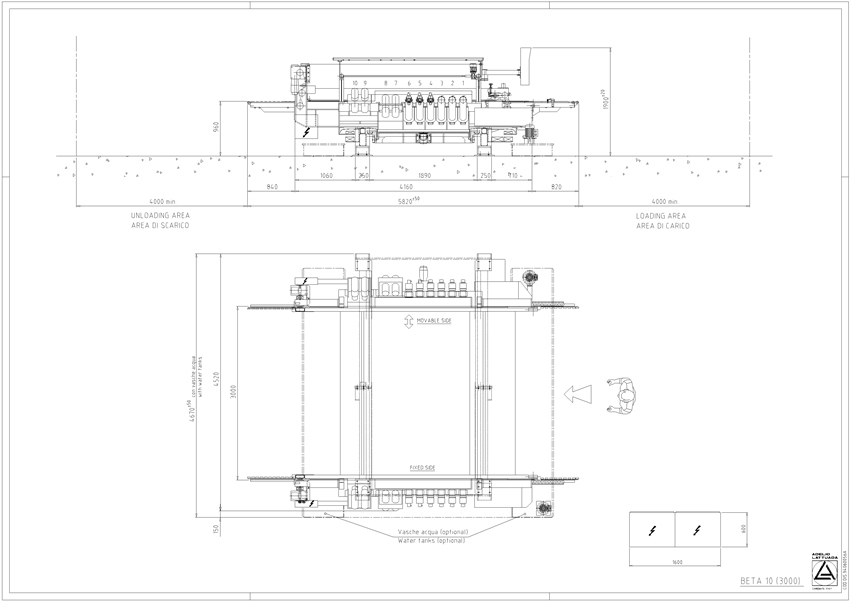

BETA 10

Double-edger for the processing of the flat edge with arris with 10 cup wheels and possibility to add one dubbing device or a cerium wheel on each side.

Equipped with an automatic system of glass squaring and centring, it also has a colour touch-screen panel, conceived in order to help the machine’s check, use and maintenance. Thanks to this panel, the operator can manage the (automatic/manual) cycle of the processings preparation, execution and monitoring with a series of very useful functions such as for instance the recording of the most frequent processing, the real-time statistics of use, the maintenance and alarms management.

At the entrance side of the machine there are two steerable panels on which we have placed the ammeters for the wheels power absorption as well as other controls which can be helpful during the glass insertion phase. The rugged and strong bedplate of the machine is realized in arc-welded steel, duly nerved in order to avoid torsion effects of the structure.

The movement transmission system is realized through a broached and toughened transmission bar, placed in a superior position with regard to the belts for guaranteeing: a better precision and durability of the bar and both the synchronism and the easy substitution of the belts. The main strong points of our double edger are the modern technologies used, the high-quality components for the electronics, the sensoristics and the automation and therefore the simple and quick setting and positioning. For this reason it is particularly suitable also for small production lots.

- Downloads/Info

- Videos

- Technical Info

Videos

Technical Info

Wheel Configuration and Technical Info

BETA.pdf