SKILL E-D – Vertical Machining Centre

8-AXIS MACHINING CENTRE FOR THE GRINDING, MILLING, DRILLING AND POLISHING OF FLAT OR SHAPED SHEET GLASS

SKILL E-D is a vertical machining centre that combines multiple processes in one machine and is capable of carrying out all processes with speed and precision. The machine combines vertical drilling and milling with the characteristics of a grinder and vertical arissing machine and can be used for any process whether it be on flat or shaped sheet glass. Its fundamental characteristic is its versatility, which allows the machine to carry out very different operations while maintaining speed and optimal precision.

SKILL E-D grinds, polishes, mills and drills, with an opposed dual head, flat or shaped sheet glass with a thickness of 4 – 20 mm and, depending on the version, can process sheet glass of a minimum of 600×300 mm and a maximum of 6000×3210 mm.

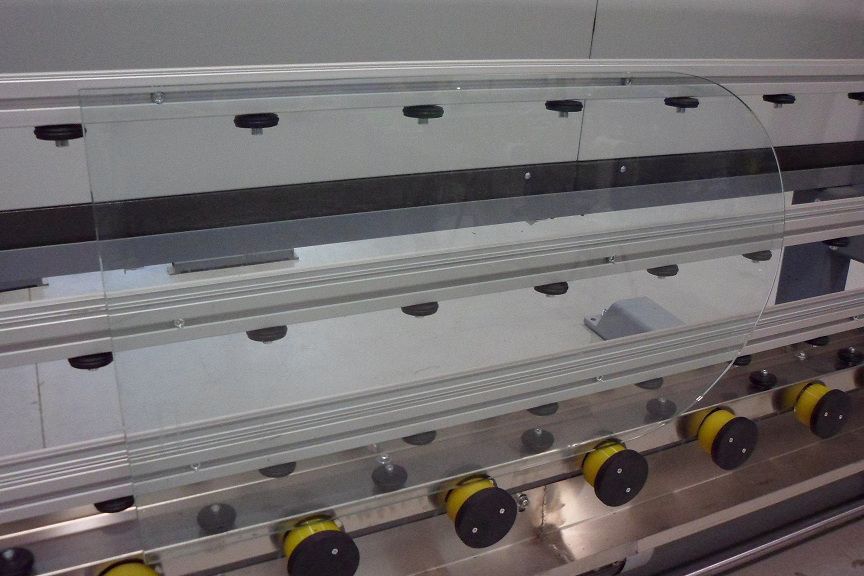

SKILL E-D has an entrance support, a central body and an exit support. The entrance roller is composed of a series of motorised wheels that transport the glass to the sheet glass scanner and another series of idle wheels (positioned opposite the first) that support the sheet glass during processing while the belts move the sheet glass. Depending on the process, the sheet glass is processed from both heads simultaneously, producing the finished product in one step.

- Downloads/Info

- Videos

- Advantages

- Processes

- Software

- Other

- Spec

Description

Videos

Advantages

The vertical processing of sheet glass has many advantages in comparison with flat processing. The size of the machine is considerably less than a corresponding flat machine and the position of the sheet glass on the roller automatically obtains the fixed zero point without error to the extent that the stroke is certain. Furthermore, horizontal machines must be perfectly even to avoid breaking the glass whereas with vertical machines, the position of the glass is naturally aligned since it is supported from underneath.

Processes

The machine can carry out multiple processes:

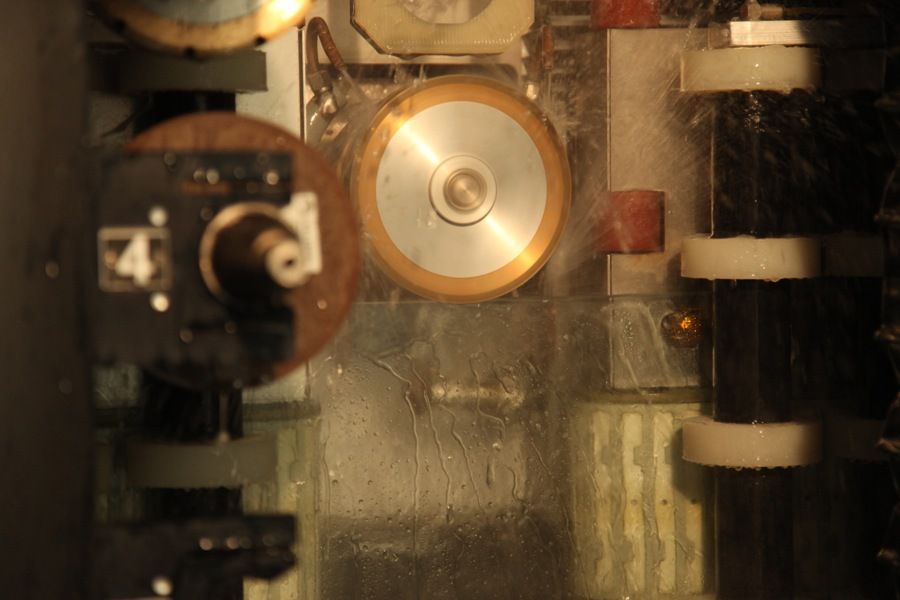

GRINDING: this process is carried out using diamond grinders with a diameter of 150 mm on flat or shaped glass, even if layered or treated.

POLISHING: it can be carried out on large surfaces with 150 mm diameter grinders or in small inserts with 50 or 30 mm grinders.

DRILLING: thanks to opposed heads, drilling is performed with maximum speed and always guarantees optimum quality and precision.

COUNTERSINKING: it can be carried out with single diamond tools controlled from the program according to the needs of the client as well as with accessories mounted on the diamond drill bits.

MILLING: thanks to the robustness and precision of the machinery, it is a simple and quick operation and by using multiple tools can mill and grind an insert in just a few seconds.

Software

The machine is managed with state of the art numerical control and uses Windows XP Professional Operating System. It is simple to use, even for beginners.

The program allows the user to control all parameters and settings as well as data regarding the tools.

The pressure of the polishing grinders is set using numerical control according to the parameters set previously so that the glass is optimally polished and finished.

A series of designs and pre-programmed processes can be inserted simply and securely into the numerical control using special software functions.

Skillglass Cad-Cam also comes with the machine and allows the operator to create any shape and design, even by importing .DXF files, to then be created by the machine. The program is parametric and is easy to use even for beginners thanks to pre-programmed shapes, which can be designed simply and quickly optimising time and the manufacture process.

Other

Automatic lubrication

The automatic lubrication system is composed of numerous lubrication points situated in the areas of most movement. A central pump regulates the continuous flow of lubrication fluid.

The constant lubrication of all moving components such as bearings, recirculating ball screws and areas of linear movement is very important to prevent malfunctions and blockages and to reduce recurring maintenance costs. The central unit reaches the lubrication points of the main line according to the quantity and frequency programmed by the operator. The entire system is controlled by the PLC and is therefore managed completely automatically.

Low-E glass processing

The processing system for low-emissivity glass (LOW-E) is a central pressure system composed of a series of rollers that, in comparison with the standard version, are made of special silicone rings and an air system of special stainless steel blowers which substitute the entrance and exit brushes in the central body of the machine.

With these new appliances the machine can process all types of glass, including extremely delicate low-emissivity glass (LOW-E).

Automatic sheet glass scanning

Flat glass can be scanned automatically thanks to a mechanical sensor that scans the height of the sheet glass and two high-quality laser sensors that scan the thickness and the length.

This option increases ease and speed. There is no need for the operator to program the system to process rectangular glass, even of different dimensions. The operator must simply load and unload the sheet glass. By automatically scanning the dimensions of the glass, the appropriate tool is selected from the tool store-rack according to the thickness of the glass.

Spec

| Machine dimensions with rollers | length 14250 mm x width 2910 mm x height 4500 mm |

| Min. size of glass worked | 600 x 300 mm |

| Max. size of glass worked | 6000 x 3210 mm |

| Min. thickness of glass worked | 4 mm |

| Max. thickness of glass worked | 20 mm |

| Height of work level | 620 mm |

| Forward work speed | 0 -15 m/min. approx. |

| Cross traverse – Y axis | 3210 mm |

| Longitudinal traverse – X axis | 6000 mm |

| Electrical power supply (standard) | 400 V 50 Hz 3 phase |

| Total installed power of machine system | 30 kW |

| Rated power of spindle. N° 2 of: | 10 kW (13,6 HP) each |

| Spindle speed with internal cooling of the tool | 0 – 12.000 rev/min |

| Numeric Control NC 1600 | 8 axis |

| N. of automatic change tool slots | 10×2 |